Precision Faceting a “Story Gemstone" PART 3

|

Faceted gemstones today are amazing pieces of craft and art compared to gemstones cut twenty years ago. The differences are created by using modern tools, such as precision and handcrafted faceting machines along with state of the art cutting/polishing laps and abrasives/polishes.

|

The Story

|

Moon and Sunshine are a local couple that heard about my work and contacted me by phone about their desire for precision faceted gemstone. They were going to have a small private ceremony on the Summer Solstice to celebrate their union as a couple and wanted to have two stones faceted for the occasion. Both of them had their own alternative ideas about the ceremony and the exchange of rings and gemstones. We arranged a meeting at a local coffee house to discuss their story. Moon was interested in a traditional white gold and diamond style ring, but her ethics would not let her support the gold or diamond industries. She showed me a natural quartz crystal point that Sunshine had given her early in the relationship and asked if I could create a gemstone design using the quartz crystal. The crystal was exceptionally clear and the correct size for her silver ring and would work perfectly. Sunshine did not want to wear a ring due to his job as an organic farmer and the possibility of loss or damage, but instead he wanted Moon to give him a single golden yellow stone as a symbol of their relationship at the ceremony. He also was interested in me creating a design for the stone. I showed them several designs during our meetings and he chose one of my sought after collector stone designs. He asked me about making their stones unique and I assured than that I could add embellishments that would add beauty and individuality. I met with Moon and Sunshine two additional times to verify the selection of Sunshine’s rough stone and to sign off on the designs. I was honored when they invited me to the ceremony and made me a part of their story.

|

Step 3

A precision facetor uses a very different level of equipment than the factory production gemstone cutter. The main differences are in the price of the equipment and the precision and perfection that the equipment allows. The overseas factory is more interested in bulk production at a profit that will sustain the company and its owners. This calls for controlling costs and output first and putting quality second, whereas a precision facetor will put quality first. This quality comes with the use of the best equipment and polishes available along with taking into account the gemstone properties and precise angles.

The main piece of equipment for faceting gemstones is the faceting machine. The faceting machine has progressively developed to an exacting and precise tool over the past 200 years. I recommend reading Glenn Klein’s book “Evolution of Faceting Machines,” found at: http://www.glennklein.com for a delightful and picture-full journey of the development of the faceting machine. The current state-of-the-art faceting machine can facet with the precision of one-thousandth of a centimeter. The professional faceting machine can now be used and combined with new machines that will allow for concave and fantasy facets, enabling the precision facetor the ability to sculpt the gemstone in ways unimagined several decades ago. This new style of faceting is creating gemstones that move the craft from design to sculptural art. New tools for faceting are being developed and tested by Hashnu Stones & Gems as well as other precision facetors on a regular basis at this time. Along with the new tools have come new laps and polishes for cutting and polishing the gemstone. Discoveries of new materials, compounds, and rare earth minerals have allowed for the development of new lap fabrication and finer polishes and moved the craft of faceting at an exceedingly fast pace over the last decade, allowing for finer detail and extraordinary polishes. The combination of more precise faceting machines, new carving and fantasy tools, along with sophisticated cutting and polishing compounds, has inspired precision gemstone facetors to develop new techniques and in turn, create new and wonderful artistic expressions in the craft and art of gemstone faceting. Based on this, I would be bold enough to say that we are now in the middle of a gemstone faceting and lapidary renaissance. While these tools and techniques will eventually become affordable and standardized for the gemstone factory over the years, today, the precision facetor is both the architect and gateway to the cutting edge of the modern gemstone. |

|

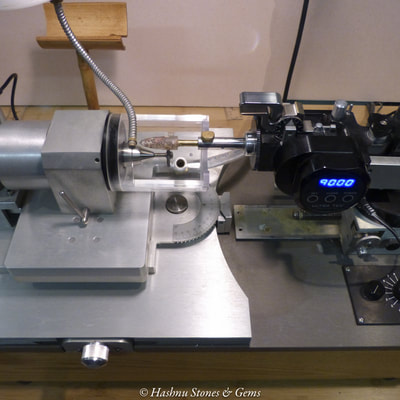

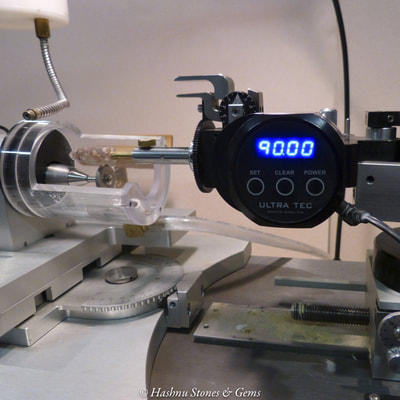

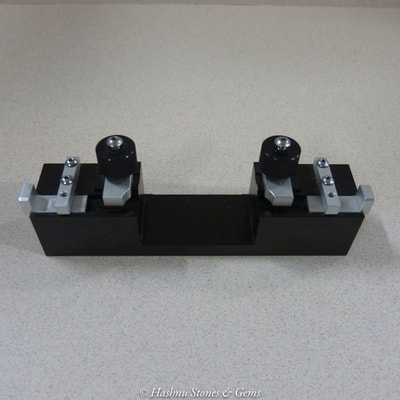

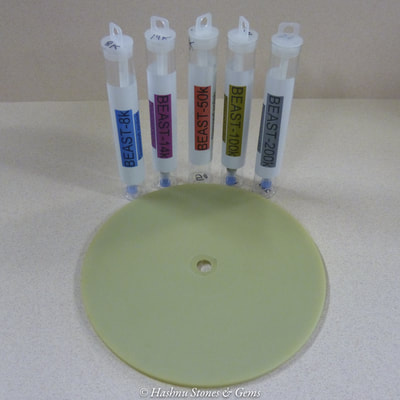

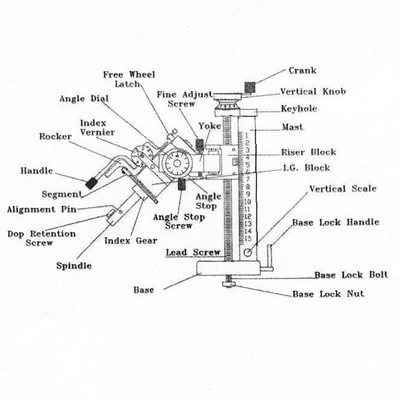

3.1 ULTRA TEC V5 Faceting Machine setup at Hashnu Stones & Gems Studio

3.2 ULTRA TEC V5 Faceting Machine being used with the Gearloose Matrix Lap polishing Quartz 3.3 ULTRA TEC Fantasy Machine setup at Hashnu Stones & Gems Studio 3.4 ULTRA TEC Fantasy Machine being used to carve a concave facet on a Clorite Quartz Pendulum 3.5 ULTRA TEC Transfer Jig used for transferring gemstones in order to facet both the pavilion and crown 3.6 Crystalite Plated 260 Grit Lap & Inland Sintered 600 Grit Lap used for grinding (cutting) the gemstones in the early phase of faceting. 3.7 Hyper-Edge1,500 Hyper-Edge Lap used for the final stage of cutting before the pre-polish stage 3.8 Lighting Lap Natural Lap and Beast Polish used with various diamond grits for faceting, pre-polishing and polishing - we use it mostly for pre-polishing and matte finishes 3.9 Gearloose Lapidary Oxides, Diamonds & Snake Oil used for polishing various types of gemstones 3.10 Gearloose Lapidary DiaMatrix Polishing Lap and 100,000 & 200,000 Diamond Polish used for the ultimate polish on harder gemstones like Ruby and Sapphire 3.11 Assorted Tools for Fantasy Machine used by Hashnu Stones & Gems for carving artistic embellishments in gemstones 3.12 Faceting machine nomenclature provided by ULTRA TEC |